Shear Cut Knifeholder

Pneumatic Shear Knifeholder

MT-A410

MT-A410 is the popular shear knife-holder in many slitting applications. It equipped 90mm top blade for general shear slitting propose and characterized by two individual control valves of downstroke and side contact, not only independent control each valve but also continuous automatic action by one valve, more convenient and flexible for online operation. Besides the depth adjustment screw provide adjustable downstroke to control overlap modularized component design has improved quality and reduce costs to offer a new knife-holder option. MT-A410 offers a wide range of slitting material including plastic, paper, copper foil…etc., thickness under 0.4mm and slit width within 45mm application.

Slim Pneumatic Shear Knifeholder

MT-A425

MT-A425 features a compact design and costeffective and in the shear knife-holder category. It is specialized in narrow slitting application, which minimum slit width up to 28mm. The new swing design provides stable side contact force to getting a better slitting effect. It also equips two individual control valves of down stroke and side contact, not only independent control each valve but also continuous action by one valve, more convenient and flexible for online operation. The modularized component design has improved quality and reduce costs to offer a new knife-holder option. It is optimally suited to light web slitting tasks with under 0.3mm thickness material like paper, plastic film, non-woven fibers and others.

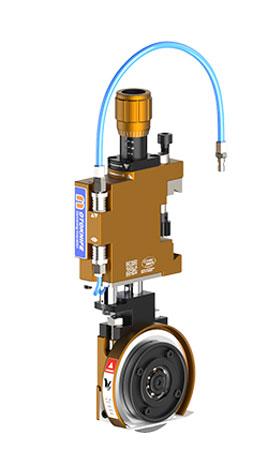

Pneumatic Shear Knifeholder

MT-A450

MT-A450 is new designed for flexible application and improving operational efficiency. It has cant angle adjustable and replaceable bottom make easier to use at different web direction. The new function, self flow control can prevent damage blade when operation, and another Iike micrometer, with the same structure the micro depth adjustment, enhance control overlap distance accuracy up to 0.05mm. Standard knife holder equips ø90mm top blade, it can also choice 450L for ø105mm top blade. MT-A450 offers a wide range of slitting material including plastic, paper, copper foil..etc., thickness under 0.4mm and slit width within 53mm applications.

Heavy-duty Pneumatic Shear Knifeholder

MT-A610

MT-A610 has aunique patent design with three cylinders and robust knife-holder to offer stable down force. Easy operation, this model including two stage action, down stroke and side stroke can be controlled by individual valves or continuous movement. Built in self-flow control is ideal for reducing the downward rate of knifeholder prevents blade damage when improper operation. New micro depth adjustment enhances control overlap distance, accuracy up to 0.05mm. Adjustable cant angle provide wide a range of different web direction application. The MT-A610 is ideal for a wide range of applications throughout a multitude of diverse shear slitting like paper, plastic film, non-woven fibers and others.

Heavy-duty Pneumatic Shear Knifeholder

MT-A650

MT-A650 has included the same unique patent t design, three cylinder robust knife-holder, individual down stroke and side stroke valves, self-flow control and accuracy micro depth adjustment as with the MT-A610 to provide easy operation and stability down force pressure when online slitting. With modular integrated bottom knife-holder, the MT-A650 handle cant angle adjustment to adapt different web path direction application, side contact limit to extend blade lifetime and offer outstanding performance. MT-A650 Knife-holder is ideally suited for paper, plastic film, non-woven fibers and others converting industry.

Heavy-duty Pneumatic Shear Knifeholder

MT-A660

MT-A660 pneumatic shear-type knife-holder equips two sets of the manual valve which able to individually or be linked to control the downstroke and sidestroke. Our patented knife-holder body is made of high-strength 6061 aluminum alloy, can provide stable downforce pressure by three-cylinder robust design, reaching the perfect slitting effect. MT-A660 can well-handle the adjustment of the cant angle for the different material path direction, also strengthen the structure to ensure the consistency of the slitting quality. With high rigidity knife-holder and the 150mm blade, MT-A660 knife-holder is ideally suited for paper, plastic film, non-woven fibers, and others converting industry material.

Heavy-duty Pneumatic Shear Knifeholder

MT-A850

MT-A850 is a deal for heavy-duty application since it has a new robust knife-holder design ensuring stable downforce and side force. Individual control valves provide two-stage action, downstroke, and sidestroke continuous or separate movement. Self-flow control and micro depth adjustment design is the key to prevent damage blade and simplifying the operation due to up to 0.05mm down stoke overlap control. New cant angle adjustment and adaptive bottom knife holder offer easy operation for different web direction application. The changeable mounting bracket can be compatible with GB guide-bar series or other different exist guide-bar systems. MT-A850 with outstanding flexibility design allows major for paper, plastic film, non-woven fibers, and other applications.

Heavy-duty Pneumatic Shear Knifeholder

MT-A880

MT-A880 is our versatile heavyduty knife-holder that is suitable for a wide range of shear slitting application. It combines extremely durable knife-holder body and 200mm top blade handle maximum slitting speed up to 2000M/min. Ideal design of micro depth adjustment, individual stroke valve, self-flow control, cant angle adjust, reversible blade cartridge, mounting bracket, are a key benefit to reduce setting time and deliver convenient operation. MT-A880 provides a highly reliable slitting performance major application is for thicker, high slitting speed paper, plastic film, non-woven fibers and others.

Copyright © 2018 Motoknife All rights reserved. Designed by LAZYWeb