All

Hot-Cut Pneumatic Knifeholder

MT-A710

MT-A710 hot-cut type knife-holder adopts the air pressure design to control the downstroke, equipped with a special heating blade that can process the slitting and melt simultaneously. The knife holder is provided with compact dimensions, rapid rising/cooling temperature, and highly stable slitting quality. Unlike conventional heating methods, MT-A710 can be heated to the required temperature within 1 minute, significantly saving warm-up time. It can also be cooled down to room temperature within a few minutes, to prevent the operator from inadvertently touching the blade to get hurt. MT-A710 can also be operated with MT-A710C the temperature controller optionally. MT-A710C using the SSR method by PID controller can control the working temperature much more precisely, ensuring the consistency of the slitting quality.

Guide-bar

GB02

GB02 is for heavy-duty applications with a rigid body. There are three holes on the frame side that can be used for fixed and air supply tube propose.

Guide-bar

GB04

GB04 is for light duty applications with fewer knife holder’s installed. It has two holes on the end for fixing to the frame and for air supply purposes.

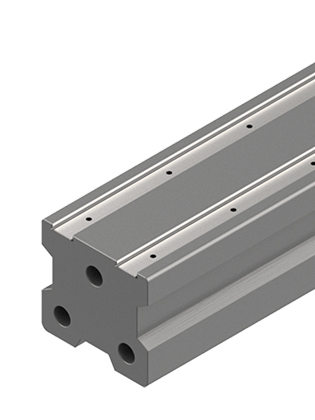

Guide-bar

GB05

GB05 is the new generation of the Guide-Bar series. It has the advantage of the linear guideway groove, side-fixed installation, lightweight, and fast delivery. Besides, there are two lengths of guide-bar to choose from, 2000mm and 2400mm.

Teeth ruler

1mm/2mm Teeth ruler

1mm/2mm Teeth ruler

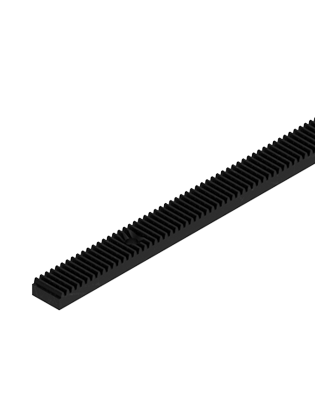

Gear rack

Gear rack

The gear rack can be equipped with GB03 or GB04. Throughout the position gear on knifeholder to mesh the gear rack, allowing it easier to move to the needed position.

Crush Cut Knives

Score knife

Slitting score knives is most commonly used for different crush cut applications such as paper, plastic film, rubber, cloth, and other thin films, etc. SKD-11 material is tool steel with good hardenability and abrasion resistance. All our knives are manufactured with excellent quality and control production at every step.

Crush Cut Knives

Perforating knife

Perforating knife is using for slitting paper, fabric ,thin plastic film, photo paper material, it can be produce in different tooth number and sizes by customer request. Perforating knife is manufacture with precision grinding machine, has excellent quality and control production at every step.

Crush Cut Knives

Precision blade

Each blade will undergo special precision grinding and control of each blade's roundness to reach +/-0.005mm before the product leaves our factory. The precision blade with fine grinding hardness backing roller and through A310/A310H half-cut knife holder depth adjusting allows you to cut as depth as you want.

Copyright © 2018 Motoknife All rights reserved. Designed by LAZYWeb