Heavy-duty Pneumatic Knifeholder

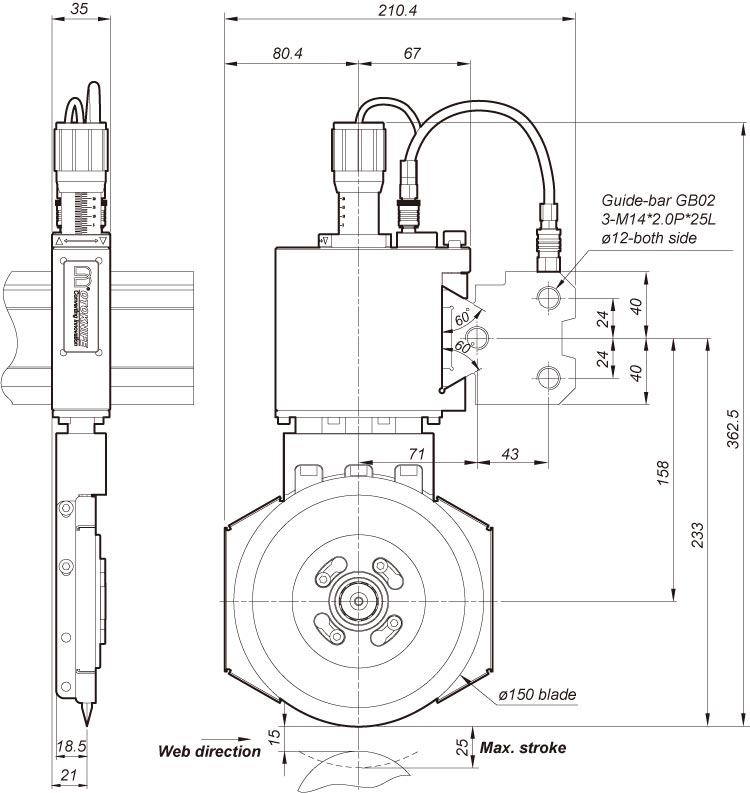

MT-A510

Introduce

MT-A510 provides a crush slitting solution that maximizes your performance and minimizes your costs. It offers a flexible solution for thicker material such as rubber, sandpaper, roofing shingles, fiberglass, paper, and plastic film, especially like multi-layer compound material as well as tissue, non-woven, and adhesive tapes. The patent design with rigid knife-holder has provided reliable downforce to perform slitting work and ensure slitting good quality for different purpose applications. Combined with self-flow control and new depth adjustment, we develop an easy solution to prevent over airflow damaged blade when downward and micro depth knob providing accuracy of up to 0.05mm downstroke control for your operator.

Model MT-A510-BSK30

.jpg)

Min. slit width 36mm

Max. slit speed 500M/min(1)

Down-stroke 0~25mm

Air Pressure 3~6/kg/cm²

Blade O.D. Ø150mm

Guide-bar GB01/GB02/GB04

Feature High rigidity knifeholder

Self flow control

Micro depth adjustment

Pentent design struture

Suitable Various Papers >>> kraft paper, silicone paper, releasing paper, decoration

wallpaper, masking paper, adhesive paper, thick paper

board, corrugated carton paper, sandpaper.

Various Plastic films >>> flexible laminated films, soft & rigid PVC films, BOPP,

PET, PE, PS, LDPE, PLA, SBS, various adhesive tape.

Cloth & fabrics >>> non-woven cloth, synthetic leather, natural cotton, mesh

cloth, medical cloth, label cloth...etc.

Foams >>> PSP foams,PE foams..etc

Drawing

(1) The maximum slitting speed is according to the actual materials, thickness and slitting results.

Recommend

Crush Cut Knives

Precision blade

Each blade will undergo special precision grinding and control of each blade's roundness to reach +/-0.005mm before the product leaves our factory. The precision blade with fine grinding hardness backing roller and through A310/A310H half-cut knife holder depth adjusting allows you to cut as depth as you want.

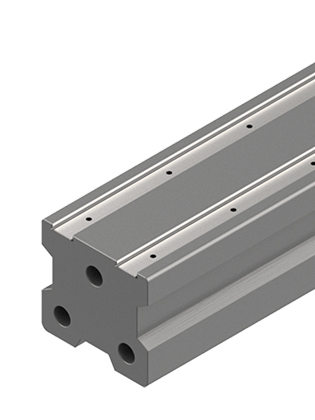

Guide-bar

GB05

GB05 is the new generation of the Guide-Bar series. It has the advantage of the linear guideway groove, side-fixed installation, lightweight, and fast delivery. Besides, there are two lengths of guide-bar to choose from, 2000mm and 2400mm.

Crush Cut Knives

130T Unibody Zigzag knife

The 130 teeth zigzag blade is made of tool steel (SKD-11) imported from Europe, processed by well heat treatment to increase its mechanical properties such as toughness and wear resistance. The blade tip is precisely ground to maintain an equal tooth pitch and peak, the slitting edge will generate the zigzag notch, to facilitate tearing along the notch. The zigzag blade is suitable for easy-tear applications such as medical tapes.

Bearing

5.0mm/6.2mm Bearing

Bearings for score blade, there are two different model , 697ZZ is for 5.0mm thickness and 17mm inner diameter score blade ; 6900RS is for 6.2mm thickness and 22mm inner diameter.

Copyright © 2018 Motoknife All rights reserved. Designed by LAZYWeb